① Number of spray guns: 4 ② Spraying disc diameter: Φ600mm ③ Material diameter: 1.2mm ④ Air pressure: 0.3-0.5Mpa ⑤ Spraying distance: Constant 80mm (adjustable) ⑥ Equipment power: Max. 8KW ⑦ Casing color: Toyota White ⑧ Control system: PLC + touch screen; all technical parameters can be set on the touch screen.

EmailMore

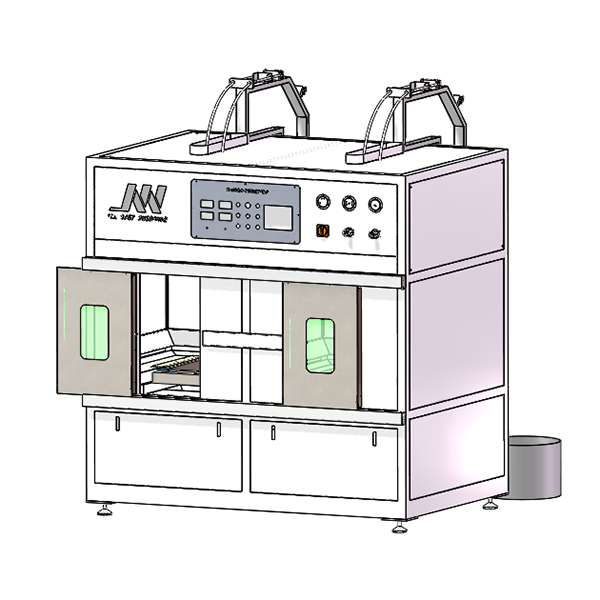

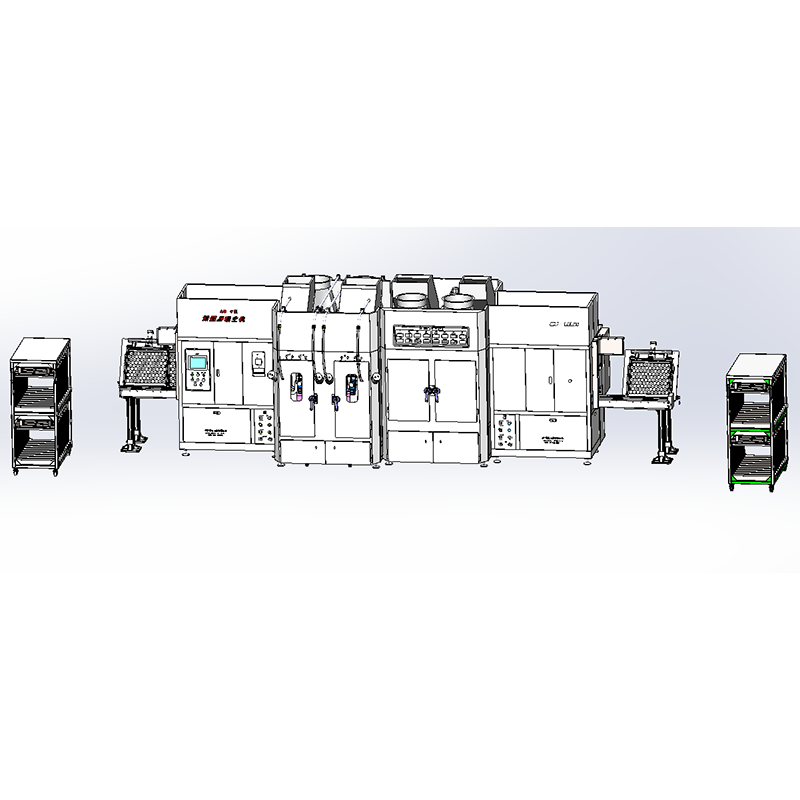

① External Dimensions: 2.5×1.45×2.1 meters ② Fixture: 480×380mm (net dimensions) ③ Number of Guns: 4 guns ④ Dust Removal Method: Top air intake, top exhaust ⑤ Wire Feeding Method: Front and rear wire feeding ⑥ Gun Chamber Layout: 2+2 ⑦ Operation Method: Synchronous belt support type ⑧ Feeding Method: Manual hanging frame

EmailMore

① Dimensions: 1.535 × 0.86 × 2.03 meters ② Number of Guns: 2 (1 dual-head gun) ③ Wire Feeding Method: Rear Wire Feeding ④ Operating Mode: Stepper Drive

EmailMore

① Dimensions: 1.535 × 0.86 × 2.03 meters ② Number of guns: 1 gun ③ Wire feeding method: Rear wire feeding ④ Operating mode: Motor driven

EmailMore

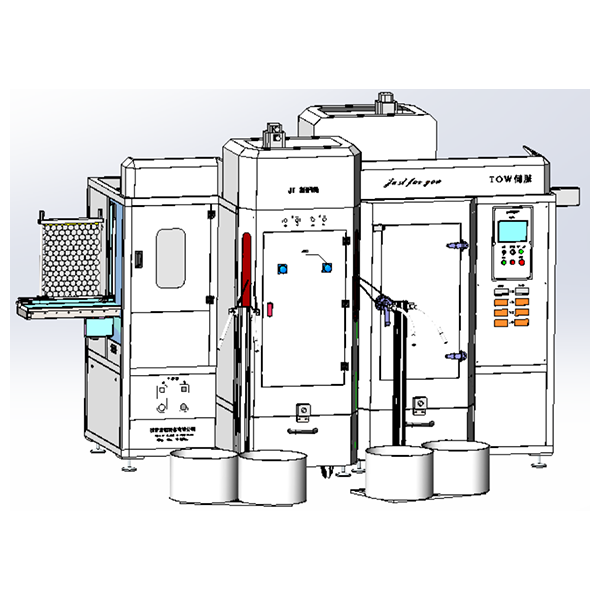

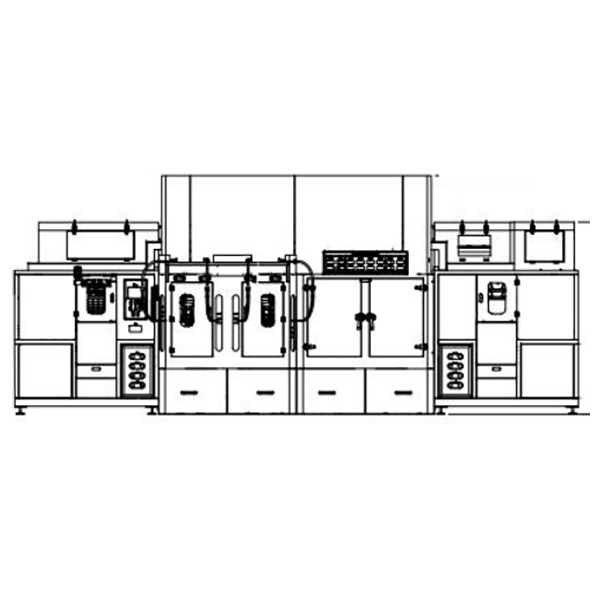

① External Dimensions: 9.0 x 3.0 x 2.5 meters ② Clamp: 550 * 580 mm ③ Number of Guns: 16 guns (8 double-headed guns) ④ Dust Removal Method: Top air intake, top exhaust ⑤ Wire Feeding Method: Rear wire feeding ⑥ Gun Chamber Layout: 8+8 ⑦ Operation Method: Synchronous belt support type ⑧ Feeding Method: Automatic frame hanging (inlet and outlet loading and unloading)

EmailMore

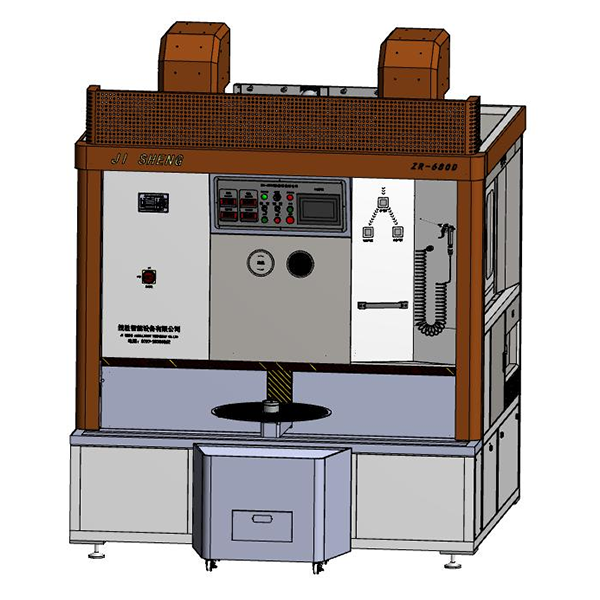

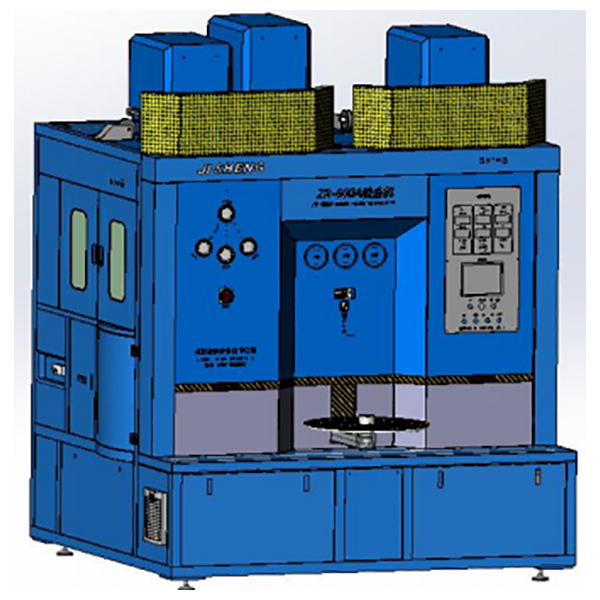

① External dimensions: 2.1 × 1.95 × 2.38 meters ② Number of guns: 3 (single-head gun) ③ Dust collection method: Tail pull ④ Wire feeding method: Rear wire feeding ⑤ Central mechanism

EmailMore

(1) The cabinet is welded with square tubes and cold-rolled plates, and the surface is thermally sprayed after rust removal. The cabinet has good sealing and uses three layers of imported sound insulation materials for noise reduction. (2) From left to right, there are two spray chambers, namely: A spray chamber with guns 1-3 on the front and B spray chamber with guns 3-6 on the back, forming a 3+3 spray mode. The spray gun scanning adopts a servo system, and the gun distance of each spray gun can be adjusted independently.

EmailMore

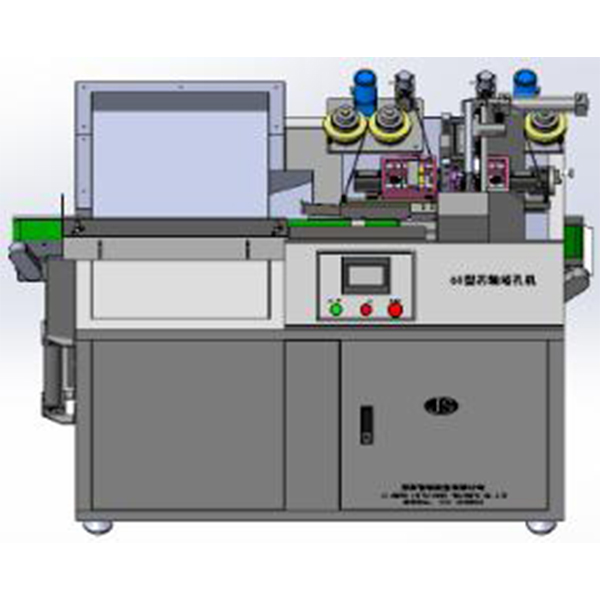

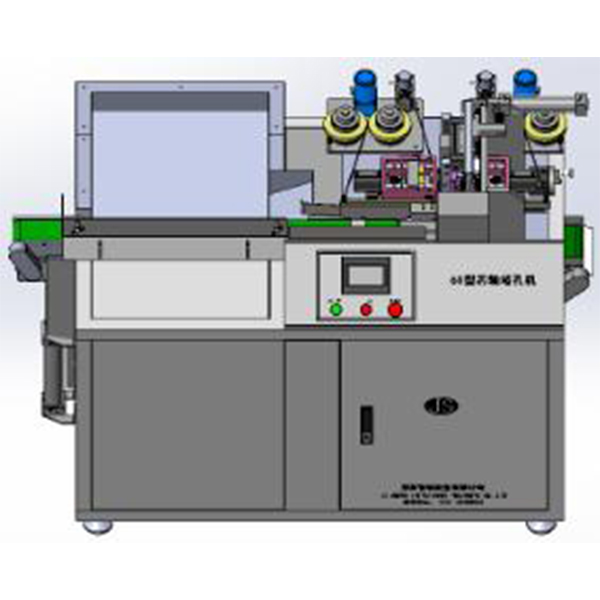

1 Core Specifications: Diameter 30-60mm; Length 40-100mm 2 Plugging Speed: Approximately 1000 pieces/hour 3 Adhesion Strength: No peeling before gold spraying, no shrinkage after gold spraying 4 Operating Mode: Automatic loading, automatic plugging of both ends at a time 5 Control Mode: PLC + Stepper Motor 6 Consumables: High-temperature tape 0.1×14 (available in rolls, cost ≤ 0.2 yuan/100 pieces) 7 Power Supply: 220V / Air Pressure 0.5-0.7MPa

EmailMore

1 Core Specifications: Diameter 16-30mm; Length 30-60mm 2 Plugging Speed: Approximately 1000 pieces/hour 3 Adhesion Strength: No peeling before gold spraying, no shrinkage after gold spraying 4 Operating Mode: Automatic loading, automatic plugging of both ends at once 5 Control Mode: PLC + Stepper Motor 6 Consumables: High-temperature tape 0.1×14" (available in rolls, cost ≤ 0.2 yuan/100 pieces) 7 Power Supply: 220V / Air Pressure 0.5-0.7MPa

EmailMore