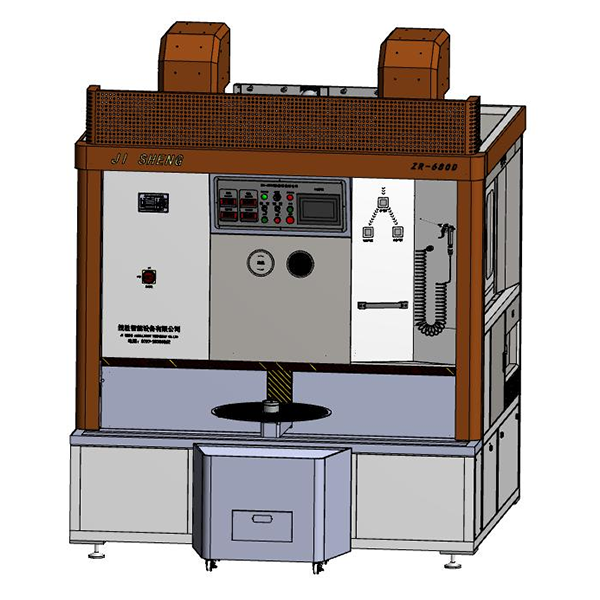

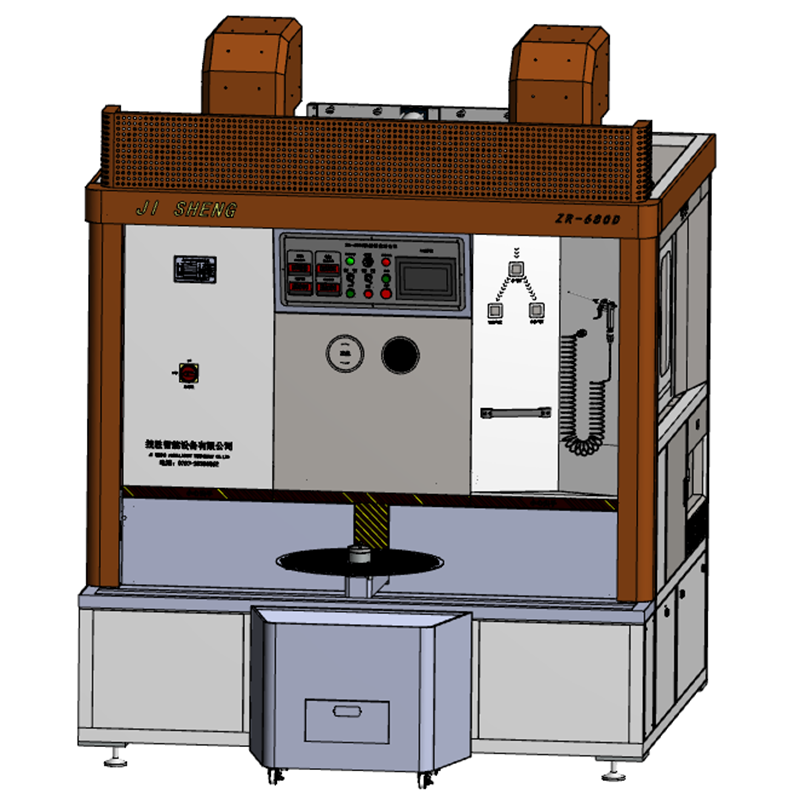

① Number of spray guns: 4 ② Spraying disc diameter: Φ600mm ③ Material diameter: 1.2mm ④ Air pressure: 0.3-0.5Mpa ⑤ Spraying distance: Constant 80mm (adjustable) ⑥ Equipment power: Max. 8KW ⑦ Casing color: Toyota White ⑧ Control system: PLC + touch screen; all technical parameters can be set on the touch screen.

EmailMore

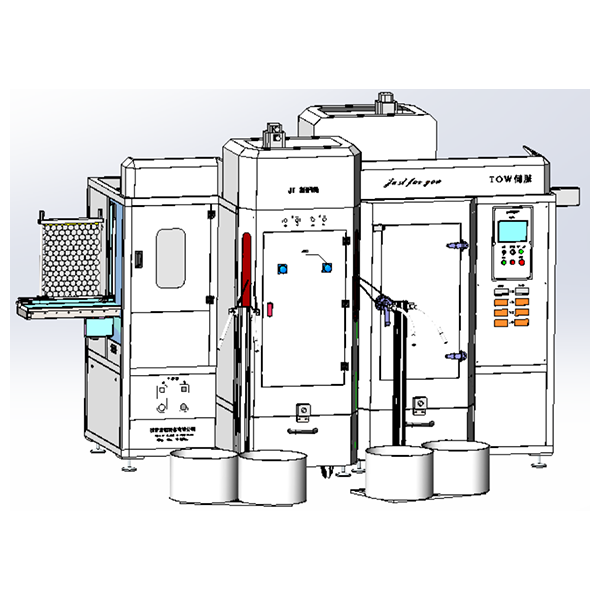

① External Dimensions: 2.5×1.45×2.1 meters ② Fixture: 480×380mm (net dimensions) ③ Number of Guns: 4 guns ④ Dust Removal Method: Top air intake, top exhaust ⑤ Wire Feeding Method: Front and rear wire feeding ⑥ Gun Chamber Layout: 2+2 ⑦ Operation Method: Synchronous belt support type ⑧ Feeding Method: Manual hanging frame

EmailMore

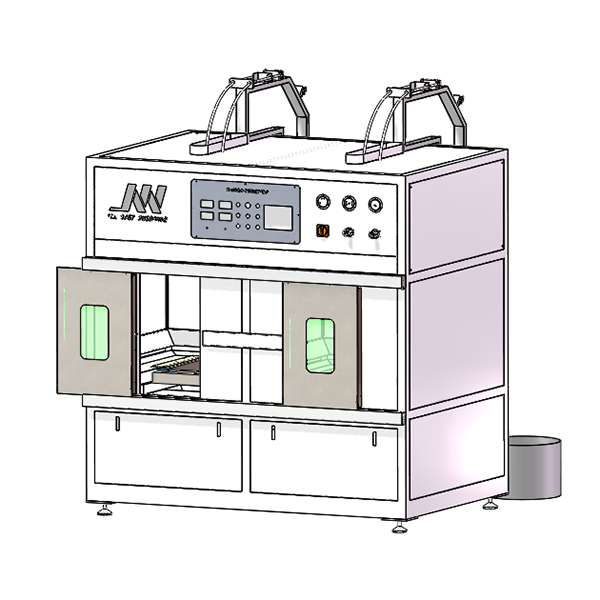

① Dimensions: 1.535 × 0.86 × 2.03 meters ② Number of Guns: 2 (1 dual-head gun) ③ Wire Feeding Method: Rear Wire Feeding ④ Operating Mode: Stepper Drive

EmailMore

① Dimensions: 1.535 × 0.86 × 2.03 meters ② Number of guns: 1 gun ③ Wire feeding method: Rear wire feeding ④ Operating mode: Motor driven

EmailMore

2.1 The equipment cabinet is welded from square tubes and cold-rolled steel, derusted and painted before being surface-sprayed. The cabinet is well-sealed, uses three layers of imported soundproofing material for soundproofing, and is equipped with a hollow tempered glass observation window. 2.2 The equipment has two spray chambers, one on the left and one on the right, equipped with two independently developed spray guns: the first in the left spray chamber and the second in the right, creating a 1+1 spray pattern.

EmailMore

This product is suitable for spraying metal on flat or round metallized capacitor cores. It utilizes a 6-gun, 4-rotary-disc design, employing three double-headed spray guns, one in each of three spray chambers. The guns are isolated by bell jars to minimize ozone and dust contamination. It features intelligent operation, high spray efficiency, high material utilization, low energy consumption, and low noise.

EmailMore

2.1.1 The frame is reliable, and the chassis and frame are considered to be rectangular or square tubes with moderate thickness, which are fully welded and have no deformation phenomenon during handling and use; 2.1.2 There are four workstations in total, three metal spraying workstations with three dust-proof bell covers, forming three independent metal spraying rooms and three independent air ducts, and another workstation is the flip side work station.

EmailMore