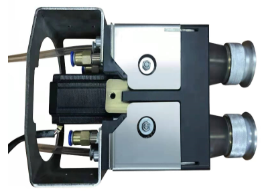

1. Spray Gun Introduction

This gun is designed for a Ø1.2mm wire diameter and features a "targeted" spraying design. Its spray radius is less than 15mm, and the gun distance can be fixed at 80mm for pure zinc spraying and 50mm for zinc-tin alloy spraying. This effectively improves spray material utilization and equipment efficiency while significantly reducing compressed air usage and saving energy. It features smooth wire feeding, no wire clogging, no sparking, and produces uniform, fine, and highly adherent gold particles with low oxidation resistance and easy welding.

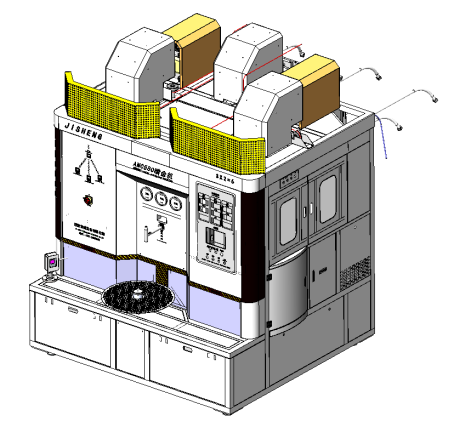

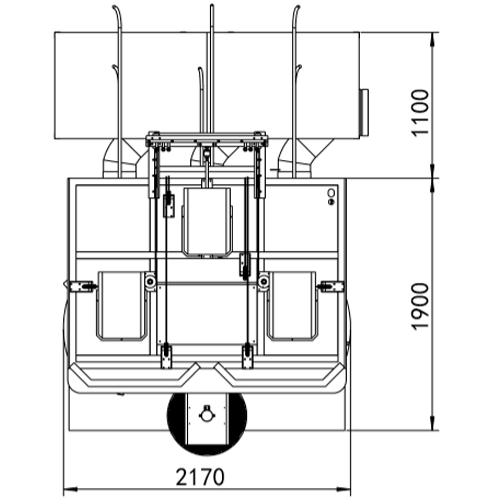

2. Appearance of the equipment (reference picture, subject to the final design)

3 Equipment Structure Description

3.1 Equipment Frame and Spraying Chamber

3.1.1 The frame is sturdy. The chassis and frame are constructed of rectangular or square tubes of appropriate thickness, fully welded, and exhibit no deformation during handling or use.

3.1.2 Each chamber has four workstations. Three spraying stations are equipped with three dustproof bell covers, forming three independent spraying chambers. The third station is a flipping station.

3.1.3 The spraying chamber is airtight and soundproof, with a three-layer soundproofing design. It is equipped with an automatic stainless steel gate that automatically closes during spraying operations and retracts when switching between workstations. 3.2 Spray Gun Scanning Components and Control

3.2.1 A servo system drives the lead screw, allowing the spray gun to scan along the pallet's radius.

3.2.2 Utilizes PLC, touch screen, and servo control.

3.3 Spray Gun and Wire Feed Mechanism

3.3.1 Equipped with three sets of six newly developed, dual-head spray guns from Jisheng.

3.3.2 The spray wire is placed at the rear of the machine, and a motor drives the wire feed gear to feed the wire into the spray gun.

4 Operating Mode

4.1 The spraying pallet rotates at a constant speed, and the spray gun moves from the outer circumference of the pallet to the inner circumference, scanning and spraying.

4.2 After spraying one side, the second side is manually flipped over for spraying.

5. Disc Diameter Inspection;

5.1 Four FR4 spray-coated trays, 600mm in diameter;

5.2 Laser rangefinder for disc diameter inspection;

5.3 Ultrasonic core height inspection;

6. Equipment Energy Requirements

6.1 Electrical Requirements: Three-phase, five-wire AC 380V, 50Hz, rated power: 12kW;

6.2 Compressed Air Requirements: Ensure stable input pressure of 0.5-0.7MPa. Compressed air must be dry and free of moisture. The air inlet pipe must be 1-inch diameter.

7. Equipment Operating Principle

This equipment utilizes two charged spray-coated wires that collide during movement, generating a short-circuit current and high temperatures that rapidly melt the wires. The molten metal is then sprayed onto the component by high-velocity compressed air, forming a gold coating. This AMC580 intelligent spray-coated machine rotates clockwise, with left-input and right-out. Each disc is sprayed three times to meet the required coating requirements.

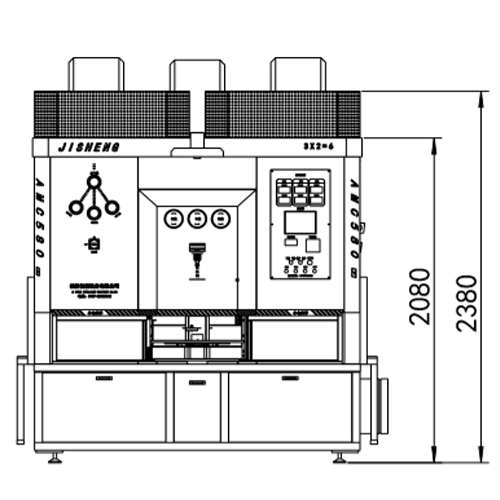

8. Equipment Main Technical Parameters

No. | Item | Parameter |

1 | Spraying material | Zinc, zinc-tin alloy |

2 | Material diameter | 1.2mm |

3 | Number of spray guns | 3×2=6 |

4 | Wire feed speed | Max.8m/min |

5 | Spraying plate diameter | Φ600mm |

6 | Equipment station | 4 |

7 | Suitable core height | ≤120mm |

8 | Spraying distance | 80mm constant (high utilization rate) |

9 | Control system | PLC+touch screen, technical parameters can be set on the touch screen, fault alarm is displayed in Chinese |

10 | Equipment power supply | Three-phase 380VAC, 50Hz |

11 | Equipment power | Max.12KW |

12 | Wire feed current | Up to 120A |

13 | Required compressed air pressure | 0.5-0.7Mpa |

14 | Equipment operating pressure | 0.25-0.4Mpa |

15 | Dust cover | 3 independent metal-sprayed dust covers |

16 | Dust removal air volume requirements | ≥5500m3/h |

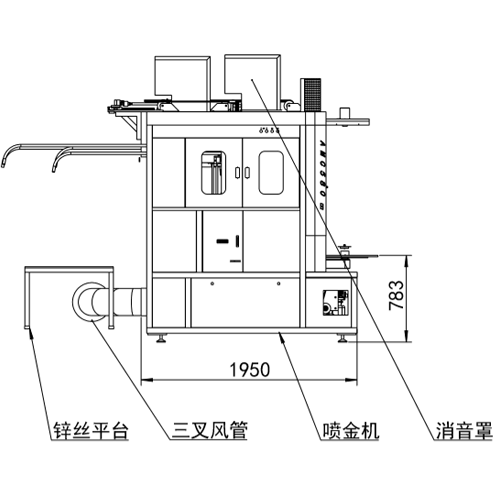

17 | Equipment dimensions | 2170×1950×2380(L×W×H) |

18 | Equipment weight | 1800Kg |

19 | Casing color | white |

9. Brands of main components of the equipment

No. | Item | Brand |

1 | PLC | Delta |

2 | Touch screens | Display Control |

3 | Circuit breakers, contactors | Schneider |

4 | Pneumatic cylinders, solenoid valves | AirTac |

5 | Servos | Delta |

6 | Sensors, relays | Autonics |

7 | Motors | Jinyan |

10. Environmental safety standards of equipment

No. | Item | Require |

1 | Electrical interlocks | The equipment features reliable protection against electric shock, eliminating any potential safety hazards from external electrical contact. |

2 | Noise and exhaust fumes | Noise level is ≤85dB, and exhaust emissions comply with national and industry standards. |

3 | Protective devices | Reliable protective devices are installed in hazardous locations on the equipment, and clear warning signs are affixed. |

4 | Signage layout | All markings comply with national standards. |

5 | Electrical requirements | The wiring system complies with national safety standards, with switch capacity matched to the equipment load and effective electrical grounding and leakage protection devices. |

11. List of equipment wearing parts

No. | Item |

1 | Nozzle |

2 | Wire feed roller |

3 | Wire pressing roller |

4 | Electrode |

5 | Wire feed spring tube |

12. Random accessories

No. | Item | Quantity |

1 | Tool box | 1 |

2 | Metal-sprayed trays | 4 |

3 | Diagonal pliers | 1 |

4 | Nozzles | 12 |

5 | Porcelain caps | 6 |

6 | Special electrodes | 12 |

7 | Guide wires | 12 |

8 | Nozzle guides | 12 |

9 | Operating instructions | 1 |

Equipment dimensions

Front View

Side View

Top View

We strictly adhere to international trade regulations (such as EU CE, US FCC, and Middle East SASO certifications). We provide product compliance documentation and assist customers with customs clearance, tax, and other issues to ensure smooth order delivery.

Yes! We offer flexible minimum order quantities (MOQs) and can customize logos, packaging, and features to meet customer needs. For more information, please contact your sales manager for a customized solution.

Customers can submit a sample request online. We will ship the sample within 3-7 business days and cover the basic shipping costs (negotiable for some regions). Sample turnaround time is typically 7-15 days.

We accept various payment methods, including T/T (Telegraphic Transfer), Letter of Credit (L/C), PayPal, and Alibaba Credit Guarantee, to ensure the security of your funds.