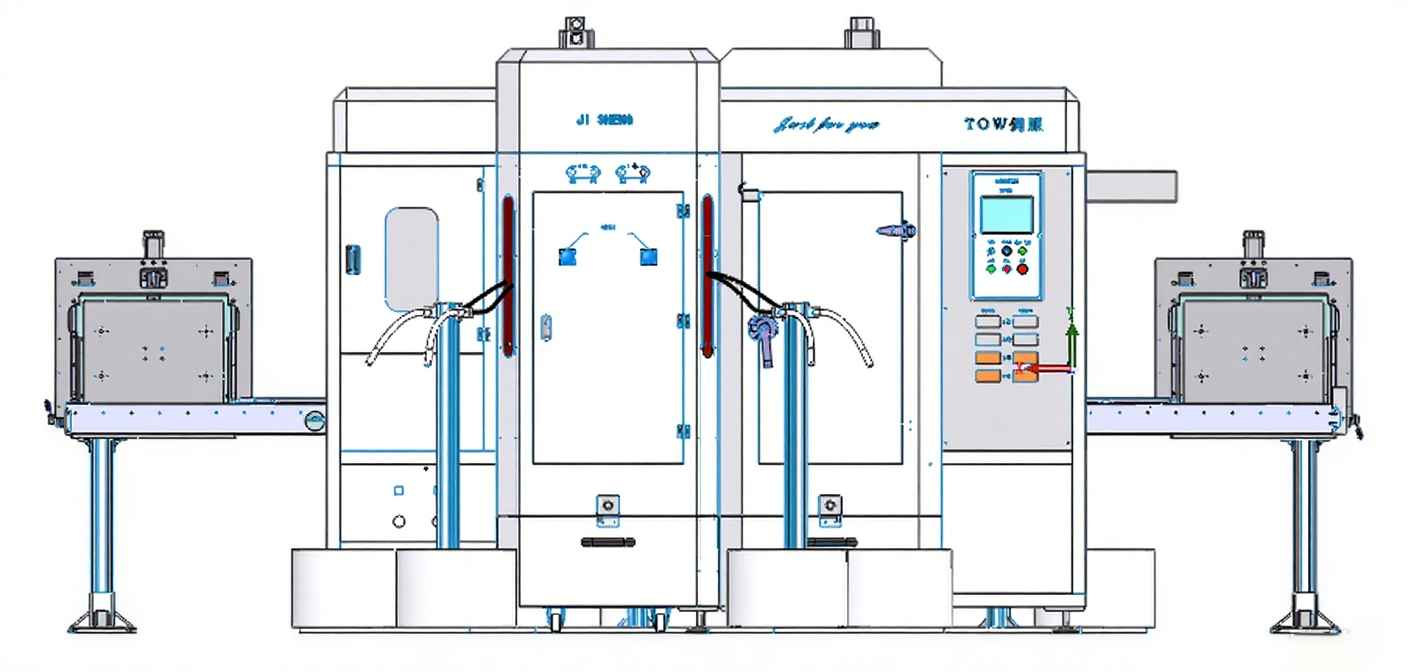

1 Appearance of the equipment (for reference only, the actual product shall prevail)

2 Structural description of the equipment

(1) The cabinet is welded with square tubes and cold-rolled plates, and the surface is thermally sprayed after rust removal. The cabinet has good sealing and uses three layers of imported sound insulation materials for noise reduction.

(2) From left to right, there are two spray chambers, namely: A spray chamber with guns 1-2 on the front and B spray chamber with guns 3-4 on the back, forming a 2+2 spray mode. The spray gun scanning adopts a servo system, and the gun distance of each spray gun can be adjusted independently.

(3) The gold spray frame conveying system has been carefully designed. The conveying is carried out by a frequency converter. The conveying system runs smoothly and is durable.

(4) The spray gun scanning adopts a servo system. The gun distance of each spray gun can be adjusted independently. The moving speed of the spray gun can be automatically adjusted through the digital input of the touch screen. The spray gun is equipped with an automatic dust blowing function. The moving speed of the gold spray frame, etc.

(5) Upper exhaust dust removal system:

a. The upper exhaust dust removal efficiency is high. Through the U-shaped wind, the air volume inside the independent cabin is enhanced, which effectively removes excess dust and reduces the pollution of the core end face.

b. The wind force in the gold spray chamber is uniform, which saves energy significantly, reduces the dust removal capacity configuration, and reduces investment.

c. The equipment is beautiful, compact and reasonable.

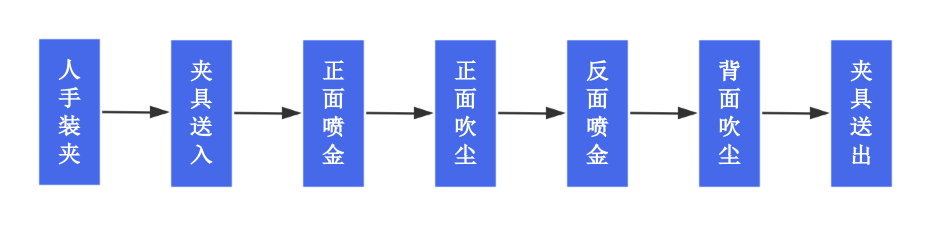

3. Working principle of the equipment

This equipment uses two charged gold spray wires to collide during movement to generate a short-circuit current and form a high temperature to make the metal wire melt rapidly. The molten metal is sprayed onto the component by high-speed compressed air to form a gold spray layer. These four-gun, two-sided, independent spray chambers utilize a left-in, right-out conveyor system. The core-loading fixture is placed on the conveyor line and moves at a constant speed. Manual loading is performed in the loading area, and the fixture is then raised and pushed onto the conveyor belt. As the core passes through spray chamber A, the spray guns move up and down to spray the front surface with four guns. When the spray fixture reaches spray chamber B, the back surface is sprayed in the same manner, achieving the desired thickness. This completes the spraying process, and the core-loading frame is then automatically transported by the conveyor belt to the unloading area for unloading.

4. Features of the equipment

(1) The equipment has good stability and is easy to operate;

(2) The spray gun uses dynamic power supply, which does not block or explode the wire;

(3) The equipment has good sealing performance;

(4) It adopts a unique design of upper exhaust for dust removal;

a. It does not form vortexes, does not turn black or blue;

b. It removes dust quickly and causes little pollution;

c. The upper exhaust method is highly efficient, and the investment in the dust removal system is 20-30% less;

(5) The equipment is equipped with temperature and humidity detection functions.

(6) Equipped with Jisheng's unique dust removal system, the use effect is more significant

5 Main parameters of the gold spraying machine

No. | Item | Requirements |

1 | Color | White |

2 | Power Supply Rated Voltage | 380V |

3 | Power Supply Voltage Fluctuation Range | ±10% |

4 | Power consumption | 38KW |

5 | Air source pressure | 0.5~0.7Mpa(Each gun has a digital pressure gauge with a lower limit alarm) |

6 | Spraying material | Zinc/Zinc-Tin Alloy |

7 | Number of spray guns | 2+2(1-2 shots on the front, 3-4 shots on the back) |

8 | Spraying material diameter | Φ1.6mm |

9 | Spraying voltage | 19-24V (adjustable) |

10 | Spraying current | <110A (digital display, adjustable) |

11 | Current fluctuation | ±1A |

12 | Spraying layer uniformity | ±0.02mm(Tested with a thickness of 0.5 mm) |

13 | Spraying layer thickness | 0.4-0.8mm Adjustable |

14 | Wire feed speed | 30-70mm/s(Adjustable, touch screen configurable) |

15 | Spraying distance | 120~200mm Continuously adjustable (set on touch screen) |

16 | Spraying frame movement speed | 0~6mm/s (Adjustable on the touch screen) |

17 | Capacitor length | 30~150mm |

18 | Operating noise | Below 85dB (tested at a distance of 2 meters) |

19 | Spray gun scanning stroke | 0-480mm, touchscreen adjustable |

20 | Scanning speed | 0-300mm/s adjustable |

21 | Compressed air temperature and humidity detection | Temperature and humidity display |

22 | Air volume detection | Air volume monitoring, insufficient air volume alarm |

22 | Automatic spraying start and stop | Memory function: restarts at the memory position after power failure |

23 | Exhaust position | Top exhaust |

24 | Equipment cleaning | The equipment is equipped with at least one air gun at each end. |

25 | Consumable parts management | Wire guide tube replacement, ceramic cap, wire feed gear, and nozzle are managed on a time basis. |

26 | Alarm function | PLC abnormality alarms, servo alarms, safety door opening alarm during operation, current alarms (wire breakage, wire blockage), gun air pressure alarms, feed inverter alarms, dust removal timeout alarms, and nozzle replacement alarms. |

27 | Dust removal air volume | ≥8000m3/h |

6. Product quality control

No. | Key Control Item | Requirement | Remarks |

1 | Gun distance | The distance of each spray gun is independently adjustable. | 120-200mm |

2 | Metal spraying layer uniformity | Metal spraying layer deviation is ±0.02mm. |

|

3 | Metal spraying adhesion | No noticeable delamination between sprayed metal layers. |

|

7. Spare parts or wearing parts

No. | Name | Specifications | Quantity |

1 | Metal-sprayed frame |

| 10 |

2 | Tool box |

| 1 |

3 | Diagonal pliers |

| 1 |

4 | Feeder electrode |

| 16 |

5 | Nozzle |

| 8 |

6 | Nozzle guide tube |

| 16 |

7 | Porcelain cap |

| 4 |

8 | Operating instructions |

| 1 |

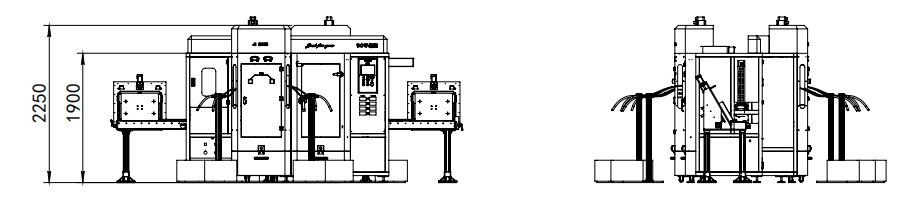

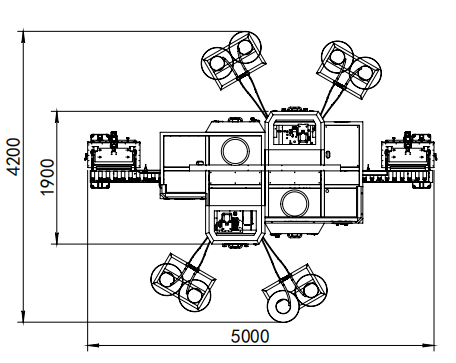

8. Equipment dimensions

We strictly adhere to international trade regulations (such as EU CE, US FCC, and Middle East SASO certifications). We provide product compliance documentation and assist customers with customs clearance, tax, and other issues to ensure smooth order delivery.

Yes! We offer flexible minimum order quantities (MOQs) and can customize logos, packaging, and features to meet customer needs. For more information, please contact your sales manager for a customized solution.

Customers can submit a sample request online. We will ship the sample within 3-7 business days and cover the basic shipping costs (negotiable for some regions). Sample turnaround time is typically 7-15 days.

We accept various payment methods, including T/T (Telegraphic Transfer), Letter of Credit (L/C), PayPal, and Alibaba Credit Guarantee, to ensure the security of your funds.