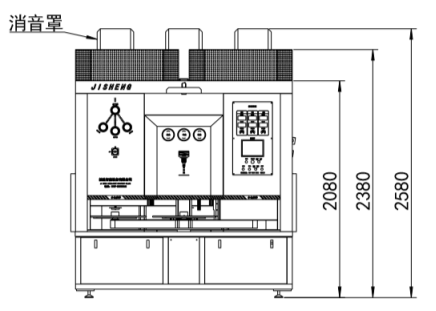

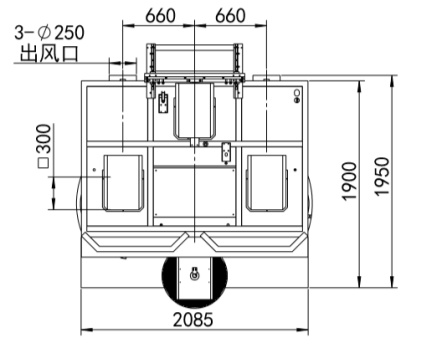

contour size of the unit

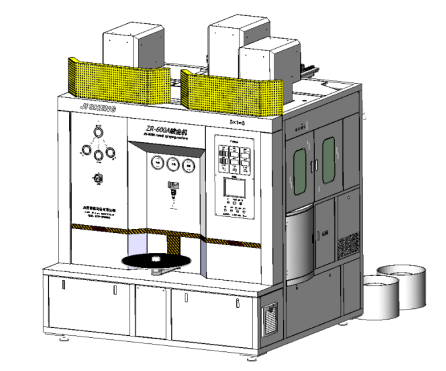

Front of equipment:

Top view of the equipment:

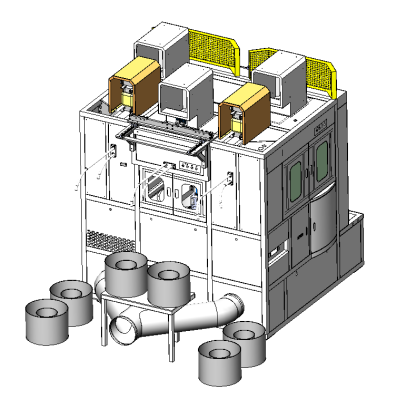

1. Equipment appearance (for reference, the final version is subject to the actual product)

2. Equipment structure description

2.1 Equipment rack and spray chamber

2.1.1 The frame is reliable, and the chassis and frame are considered to be rectangular or square tubes with moderate thickness, which are fully welded and have no deformation phenomenon during handling and use;

2.1.2 There are four workstations in total, three gold spraying workstations with three dust-proof bell covers, forming three independent gold spraying rooms and three independent air ducts, and another workstation is the flip side work station.

2.1.3 The spraying room is sealed and soundproof with three layers of sound insulation design. It is equipped with automatic stainless steel gate, which will be automatically closed during spraying operation and automatically hidden downward when switching workstations.

2.2 Spray gun scanning parts and control

2.2.1 A set of servo drives the screw rod, so that the spray gun moves along the radius of the tray for scanning;

2.2.2 PLC + touch screen + servo control is adopted

2.3 Spray gun and wire feeding mechanism

2.3.1 Three special spray guns independently developed by Jisheng Company are equipped

2.3.2 The gold wire is placed behind the equipment, and the motor drives the wire gear to send the gold wire into the spray gun;

3. Working methods

3.1 The gold spraying tray is rotated at a uniform speed, and the spraying gun scans the tray with a radius from top to bottom.

3.2 After the gold spraying is completed on one side, the second side is sprayed manually.

4. Tooling fixture and plate diameter setting

4.1 Laser detection of disc size

5. Equipment energy requirements

5.1 Electrical requirements: 3-phase five-wire AC380V,50Hz, rated power: 12KW;

5.2 Compressed air requirements: ensure the input pressure is stable, the pressure value is 0.5~0.7MPa, and the compressed air must be dry and free of moisture;

Main parameters of 6 spray gold machine:

number | project | parameter |

1 | Gold and silver | Zinc, zinc-tin alloys |

2 | Material diameter | 1.6mm |

3 | Number of guns | 3 |

4 | wire feed rate | Max.9m/min |

5 | Diameter of the spray gold plate | Φ600mm |

6 | Equipment work station | 4 |

7 | Suitable for core size | ≤75mm |

8 | The distance between the spray and the gold | Adjustable 120-180mm |

9 | Gold spew current | 30-110A |

10 | navar | PLC+ touch screen, technical parameters can be set on the touch screen, fault alarm Chinese display |

11 | device power supply | Three-phase 380VAC, 50Hz |

12 | plant capacity | Max.12KW |

13 | air pressure | System working pressure 0.5-0.7Mpa |

14 | inner structure | Equipped with 3 sets of independent gold spraying dustproof bell cover system |

15 | Dust removal air volume requirements | ≥5500m3/h |

16 | contour size of the unit | 2100×1950×2580(L×W×H) |

17 | weight of equipment | 1800Kg |

18 | Shell color | Toyota white |

19 | Plate diameter detection | Laser measurement of disc diameter |

7 Random spare parts or vulnerable parts

order number | name | Number of units |

1 | Gold-plated trays | Four |

2 | hold-all | One |

3 | diagonal pliers | 1 |

4 | Feeding electrode | Eight |

5 | Gunshot | Six |

6 | Gunpoint catheter | Six |

7 | A porcelain hat | Three |

8 | operating specification | 1 copy |

We strictly adhere to international trade regulations (such as EU CE, US FCC, and Middle East SASO certifications). We provide product compliance documentation and assist customers with customs clearance, tax, and other issues to ensure smooth order delivery.

Yes! We offer flexible minimum order quantities (MOQs) and can customize logos, packaging, and features to meet customer needs. For more information, please contact your sales manager for a customized solution.

Customers can submit a sample request online. We will ship the sample within 3-7 business days and cover the basic shipping costs (negotiable for some regions). Sample turnaround time is typically 7-15 days.

We accept various payment methods, including T/T (Telegraphic Transfer), Letter of Credit (L/C), PayPal, and Alibaba Credit Guarantee, to ensure the security of your funds.