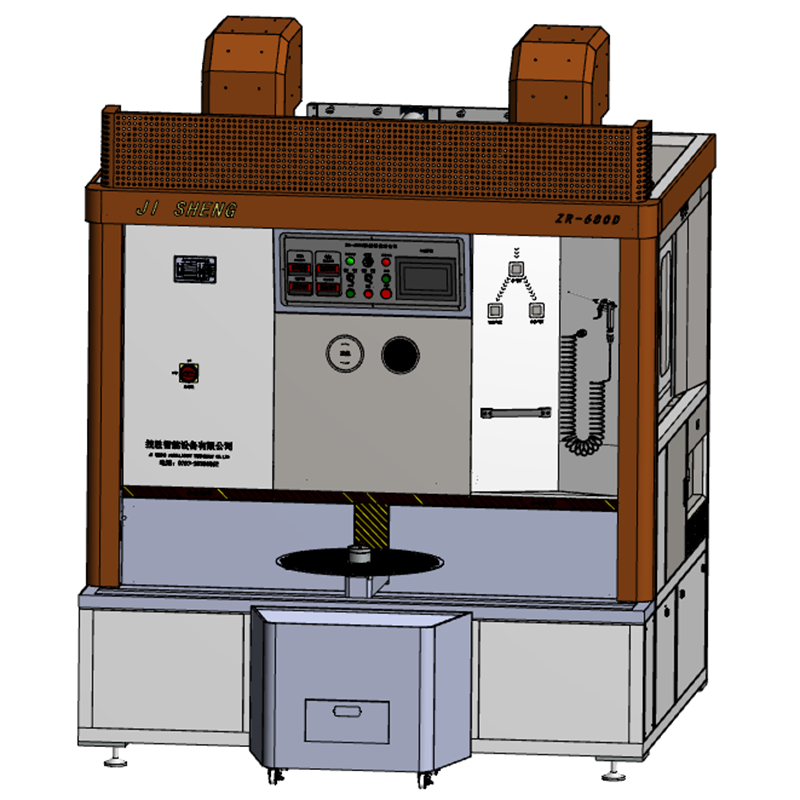

1. Appearance of the Equipment (For reference only, actual product shall prevail)

2. Equipment Structure

2.1 The equipment cabinet is welded from square tubes and cold-rolled steel, derusted and painted before being surface-sprayed. The cabinet is well-sealed, uses three layers of imported soundproofing material for soundproofing, and is equipped with a hollow tempered glass observation window.

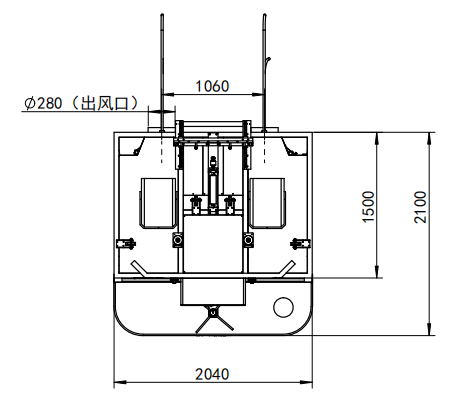

2.2 The equipment has two spray chambers, one on the left and one on the right, equipped with two independently developed spray guns: the first in the left spray chamber and the second in the right, creating a 1+1 spray pattern.

2.3 The equipment has three Each station corresponds to a Ø600mm core tray, one of which is a preparation station, and the other two are for spraying. A large rotating arm rotates clockwise.

2.4 The gun distance and movement speed of each spray gun can be automatically adjusted via digital input on the touch screen. The spray tray is set to rotate at a constant speed.

3. Equipment Working Principle

This equipment utilizes two charged spray wires that collide during movement, generating a short-circuit current and high temperatures that rapidly melt the wires. The molten metal is then sprayed onto the component by high-velocity compressed air, forming a gold coating. This two-gun, three-rotating plate spray machine rotates clockwise, with left-input and right-out. Each plate is sprayed twice to meet the required gold coating requirements.

4. Main Parameters of the Spray Machine:

No. | Item | Parameter |

1 | Spraying Material | Zinc/Zinc-Tin Alloy |

2 | Material Diameter | 1.6mm |

3 | Number of Spray Guns | 2 |

4 | Wire Feed Speed | Max.9m/min |

5 | Spraying Tray Diameter | Ø600mm |

6 | Spraying Distance | 100-180mm Adjustable |

7 | Maximum Capacitor Length | Max 90mm |

8 | Control System | PLC + Touchscreen; All Parameters Adjustable on the Touchscreen |

9 | Power | 380Vac, three-phase, 50Hz |

10 | Maximum Power | 8KW |

11 | Required Air Compressor Pressure | ≥0.6Mpa |

12 | Actual Operating Pressure | 0.4-0.5Mpa |

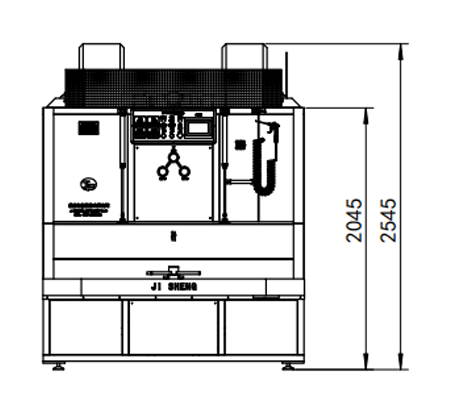

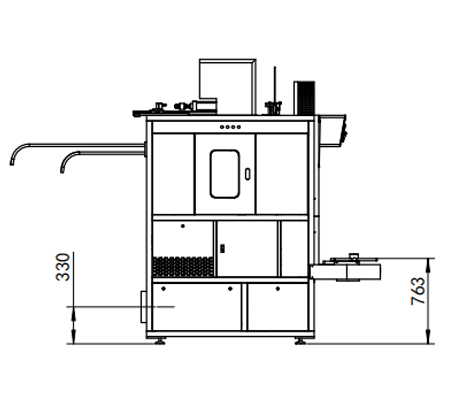

13 | Dimensions | 2040×2100×2545(L×W×H) |

14 | Weight | 1200Kg |

15 | Casing Color | Blue |

5. Equipment Wear Parts List

No. | Item | Remark |

1 | Nozzle |

|

2 | Wire feed roller |

|

3 | Wire pressing roller |

|

4 | Electrode |

|

5 | Wire feed spring tube |

6. Supplied Accessories

No. | Item | 数量 |

1 | Tool box | 1 |

2 | Diagonal pliers | 1 |

3 | Nozzle | 4 |

4 | Ceramic cap | 2 |

5 | Special electrode | 6 |

6 | Guide wire rod | 4 |

Device Dimensions

Front

Side

Top view

We strictly adhere to international trade regulations (such as EU CE, US FCC, and Middle East SASO certifications). We provide product compliance documentation and assist customers with customs clearance, tax, and other issues to ensure smooth order delivery.

Yes! We offer flexible minimum order quantities (MOQs) and can customize logos, packaging, and features to meet customer needs. For more information, please contact your sales manager for a customized solution.

Customers can submit a sample request online. We will ship the sample within 3-7 business days and cover the basic shipping costs (negotiable for some regions). Sample turnaround time is typically 7-15 days.

We accept various payment methods, including T/T (Telegraphic Transfer), Letter of Credit (L/C), PayPal, and Alibaba Credit Guarantee, to ensure the security of your funds.